Quality of Hot-dip galvanizing is one of our strength, Our CEO Mr. Lee is an expert in this field with reputation in Western-China. Our team has vast experience in HDG process and especially good at handling the tower in high corrosion areas. Galvanized standard: ISO:1461-2002.

Quality of Hot-dip galvanizing is one of our strength, Our CEO Mr. Lee is an expert in this field with reputation in Western-China. Our team has vast experience in HDG process and especially good at handling the tower in high corrosion areas. Galvanized standard: ISO:1461-2002. | Item | Thickness of zinc coating | Strength of adhesion | Corrosion by CuSo4 |

| Standard and requirement | ≧86μm | Zinc coat not be stripped and raised by hammering | 4 times |

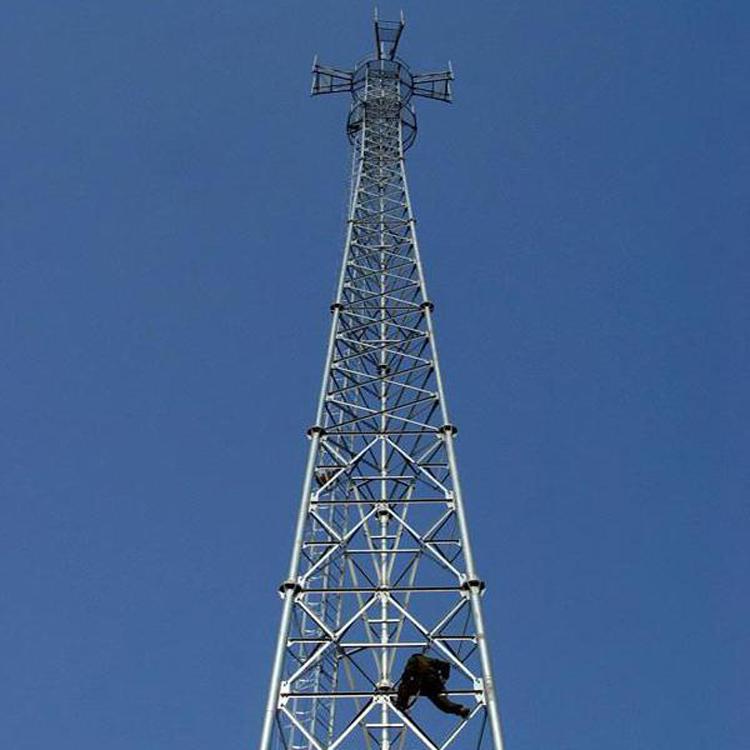

prototype tower assembly is a very traditional but effective way to inspect whether the detail drawing is correct. In some cases, clients still want to do prototype tower assembly to ensure the detail drawing and fabrication is OK. Hence, we still provide prototype tower assembly service for free to customers. In prototype tower assembly service, X.Y. Tower makes commitment: • For each member, the length, position of holes and interface with other members will be checked accurately for proper fitness; • Quantity of each member and bolts will be carefully checked from the bill of materials when assembling the prototype; • Drawings and bill of materials, sizes of bolts, fillers etc. will be revised if any mistake is found.

prototype tower assembly is a very traditional but effective way to inspect whether the detail drawing is correct. In some cases, clients still want to do prototype tower assembly to ensure the detail drawing and fabrication is OK. Hence, we still provide prototype tower assembly service for free to customers. In prototype tower assembly service, X.Y. Tower makes commitment: • For each member, the length, position of holes and interface with other members will be checked accurately for proper fitness; • Quantity of each member and bolts will be carefully checked from the bill of materials when assembling the prototype; • Drawings and bill of materials, sizes of bolts, fillers etc. will be revised if any mistake is found. Every piece of our products is coded according to the detail drawing. Every code will be put a steel seal on each piece. According to the code, clients will clearly know a single piece belong to which type and segments. All the pieces are properly numbered and packaged through the drawing which could guarantee no single piece missing and easily to be installed.

Every piece of our products is coded according to the detail drawing. Every code will be put a steel seal on each piece. According to the code, clients will clearly know a single piece belong to which type and segments. All the pieces are properly numbered and packaged through the drawing which could guarantee no single piece missing and easily to be installed.

Shipment Normally, the product will ready in 20 working days after deposit. Then the product will take 5-7 working days to arrive at Shanghai Port. For some countries or regions, like Central Asia, Myanmar, Vietnam etc., China-Europe freight train and carriage by land may be two better options of transportation.

Shipment Normally, the product will ready in 20 working days after deposit. Then the product will take 5-7 working days to arrive at Shanghai Port. For some countries or regions, like Central Asia, Myanmar, Vietnam etc., China-Europe freight train and carriage by land may be two better options of transportation.

Rooftower 12m

TESTS

Hot-dip galvanizing

Free prototype tower assembly service

Package and shipment