Guyed tower has a novel appearance,and its biggest characteristic is strengthened by using steel guy wire.

Guyed tower is a common type of communication tower which is economical and practical.

It is lighter and cheaper than the others.

It is very suitable for the geographical wide areas.

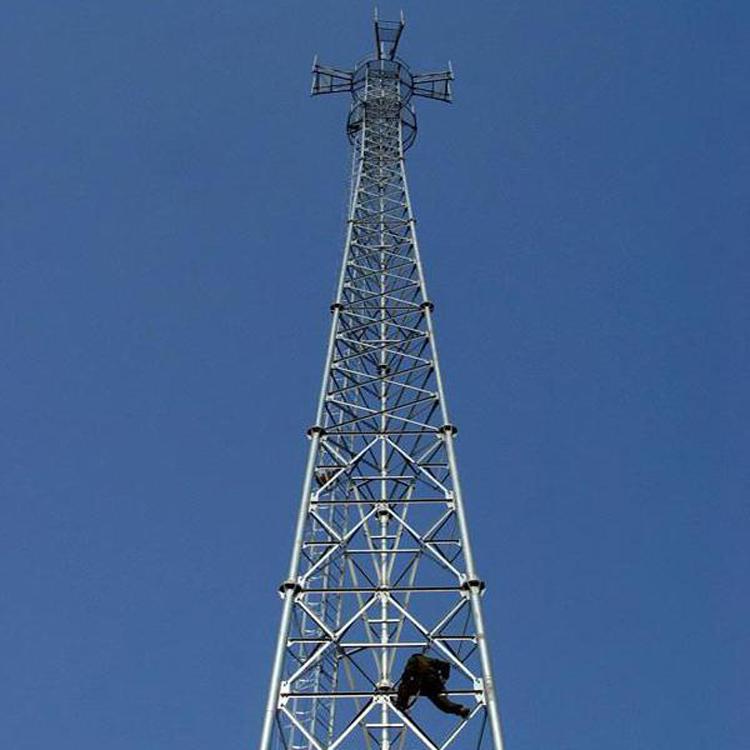

Self supporting tower usually is 3leg of 4leg tower, and its material is steel pipe or angle steel. As for the connection, tubular tower is connected by flange, and angle steel tower is connected by nuts and bolts.

Features:

1.strong wind resistance.

Small coefficient of wind load,

2.Save land resource, convenient location.

3.Convenient transportation and installation.

Single tube tower also called monopole tower, with beautiful appearance, covering an small area of 9 to 18 square meter, cost - effective , and is adopted by majority of the construction. Tower body adopt more reasonable section, which is connected through high strength bolt. It has the characteristics of easy installation and can adapt to a variety of complicated field site.

Single tube tower also called monopole tower, with beautiful appearance, covering an small area of 9 to 18 square meter, cost - effective , and is adopted by majority of the construction. Tower body adopt more reasonable section, which is connected through high strength bolt. It has the characteristics of easy installation and can adapt to a variety of complicated field site. Camouflaged Tree Tower is also a kind of cartificial trees of Bionic tree tower, on base like a real one, plus the meticulous design, when placed among the real trees in sightseeing area, park and square, it will be a part of the nature.

Camouflaged Tree Tower is also a kind of cartificial trees of Bionic tree tower, on base like a real one, plus the meticulous design, when placed among the real trees in sightseeing area, park and square, it will be a part of the nature. Features: 1. Exquisite structure, gorgeous appearance. 2. Strong structural stability, long working life. 3. Small area covering, great economic effect.

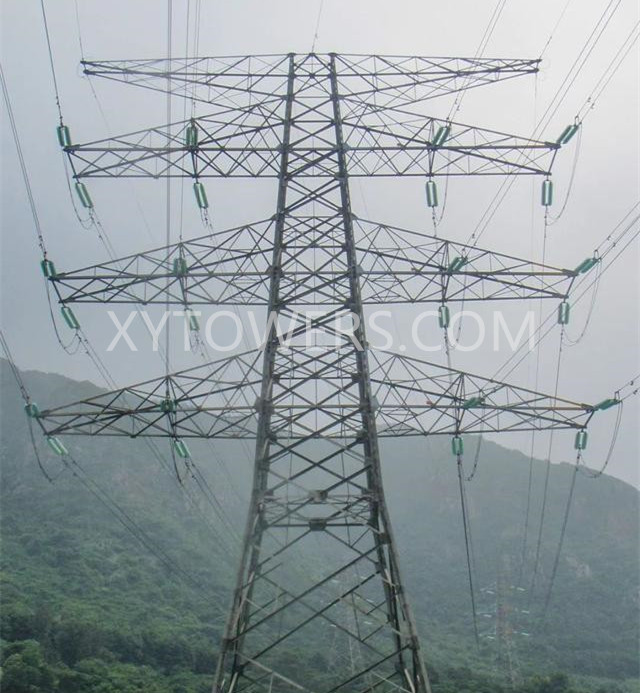

The communication tower belongs to a type of signal transmission tower, also called a signal transmission tower or a signal tower. The main function supports signal transmission and supports the signal transmitting antenna. Uses mobile/unicom/traffic satellite positioning system (GPS) and other communication departments. Fire training tower. The communication tower is composed of steel components such as tower body, platform, lightning rod, ladder, antenna support, etc., and is treated by hot-dip galvanizing and anti-corrosion treatment. It is mainly used for transmission and transmission of microwave, ultrashort wave and wireless network signals. In order to ensure the normal operation of the wireless communication system, the communication antenna is generally placed at the highest point to increase the service radius to achieve the desired communication effect. The communication antenna must have a communication tower to increase the height, so the communication tower plays an important role in the communication network system.

The communication tower belongs to a type of signal transmission tower, also called a signal transmission tower or a signal tower. The main function supports signal transmission and supports the signal transmitting antenna. Uses mobile/unicom/traffic satellite positioning system (GPS) and other communication departments. Fire training tower. The communication tower is composed of steel components such as tower body, platform, lightning rod, ladder, antenna support, etc., and is treated by hot-dip galvanizing and anti-corrosion treatment. It is mainly used for transmission and transmission of microwave, ultrashort wave and wireless network signals. In order to ensure the normal operation of the wireless communication system, the communication antenna is generally placed at the highest point to increase the service radius to achieve the desired communication effect. The communication antenna must have a communication tower to increase the height, so the communication tower plays an important role in the communication network system.| Height | From 10M-100M or according to client’s requirement |

| Shape | Polygonal or Conical |

| Material | Normally Q235B/A36,Yeild Strength≥235MPa |

| Q345B/A572,Yeild Strength≥345MPa | |

| As well as Hot Rolled coil from ASTM572, GR65,GR50,SS400 | |

| Tolerance of the dimension | According to client’s requirement |

| Surface treatment | Hot-dip-galvanized following ASTM123, or any other standard by client’s requirement |

| Joint of Poles | Slip joint, flanged connected |

| Standard | ISO9001:2015 |

| Length of per section | Within 13M once forming |

| Welding Standard | AWS(American Welding Society)D 1.1 |

| Packages | Packing with plastic paper or according to client’s requirement |

| Life Period | More than 25 years, it is according to installing environment |

| Item | Thickness of zinc coating |

| Standard and requirement | ≧86μm |

| Strength of adhesion | Corrosion by CuSo4 |

| Zinc coat not be stripped and raised by hammering | 4 times |

Factory Direct Sale,Short Lead Time,Quality Assurance,Focus on steel tower design, production and export for 5 years